We specialize in designing, building, and maintaining high-precision modules and systems for (ultra)clean environments. Our in-house RGA capabilities allow us to maintain full control over the supply chain and assembly processes. We are authorised by large customers to combine RGA analysis with certified reports and offer RGA analysis to external parties. For more information about our RGA services, please contact our sales department.

RGA Measurements

- RGA (Residual Gas Analysis) is a measurement technique which can be used to determine the vacuum cleanliness of parts.

- Parts are placed inside a high vacuum chamber (< 10-6 mbar). Contamination (for example oil and grease) is released from the part due to the high vacuum condition.

- The composition of the remaining gas molecules and atoms in the chamber, also containing the molecules released from the part is determined with the RGA.

Background Subtraction

- We measure on regular basis the outgassing values of the empty system, to determine the background values of the chamber.

- When we insert the part in the chamber and perform the RGA measurement. We measure the combined outgassing of the system (background) and the inserted part.

- After the measurement we will subtract the background values from the results of the measurement with the part.

- This gives us the net outgassing of the part.

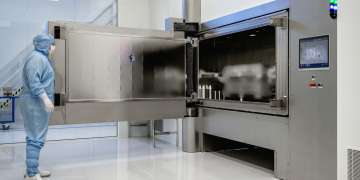

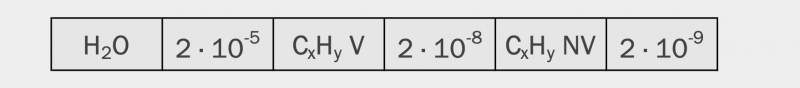

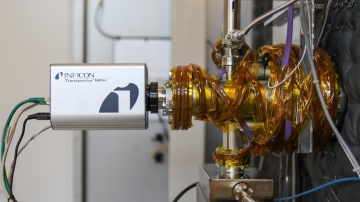

RGA - XXL

- Envelope: 2000 x 2000 x 1000 mm

(l x w x h) - Max Weight: 2000 kg

- Bake-out temperature: 200 ºC

- Metal sealed vacuum chamber with differential pumped double O-ring sealed door for low background values

- System installed in ISO 6 Cleanroom

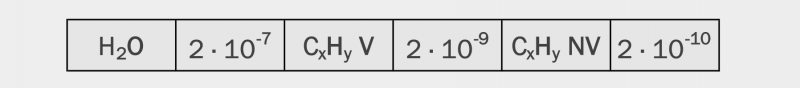

RGA - S

- Envelope: Ø 200 x 400 mm

(diameter and horizontal length) - Max Weight: 45 kg

- Bake-out temperature: 200 ºC

- Low background pressure

- Fully metal sealed vacuum chamber.

- Selectable pumping speed to optimize the signal to noise ratio for each product.

RGA Fundamentals

Ion Source

- Molecules and atoms enter the ion source by random chance.

- In the ion source a filament creates free electrons which are accelerated through the ion source and can collide with the there present molecules and atoms.

- When an electron collides with a molecule an electron is shot out of molecules orbit resulting in a positive charged ion.

- This ion can be steered by means of electrostatic fields.

- All ions are guided by the ion optics into a a straight beam that is fed into the quadrupole mass filter.

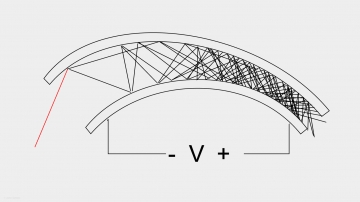

Quadrupole Mass Filter

- When the ions enter the Quadrupole mass filter they travel between four rods.

- These 4 rods are 2 pairs of 2 rods which form a low and a high pass filter, and there fore combined creating a band pass filter.

- A changing electromagnetic (RF) field on the two rod pairs brings one mass-over-charge ratio in resonance and will reject all other mass-charge-ratios.

- By changing the frequency of the electromagnetic field different masses can be brought in resonance and be passed through the filter.

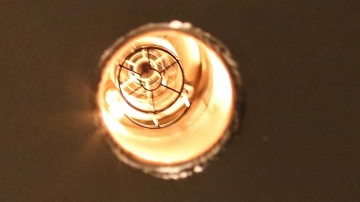

Electron Multiplier

- When the resonant ions exit the quadrupole, they are transported into the (Secondary) electron multiplier (SEM).

- This is a trumpet-shaped tube with a special coating on the inside.

- A high voltage is placed over the SEM to accelerate the ions into the SEM.

- When the ion enters the SEM and collides with the wall it will release multiple electrons.

- These electrons will in turn also collide with the wall of the SEM and create again more electrons.

Pico Ampere meter

- The electrons exiting the electron multiplier are fed into a pico ampere meter.

- The number of electrons per unit of time represents the partial pressure of the mass-over-charge-ratio selected by the quadrupole mass filter.

- Measuring the current provides a relative measurement of the amount of mass present in the selected ratio.

- By scanning a complete mass-range, the relative contents of the individual masses can be determined.

- This creates the typical bar-graph spectrum of the RGA measurement report.

Our cleaning expert explaining RGA systems

Take 10 minutes of your time, to watch Thom Bijsterbosch explaning everything about our RGA Systems, and why the footprint of our XXL System is quite unique in the world. He is being interviewed by John, our CEO.