With more than 50 years' history in Precision Parts manufacturing, we deliver parts of a higher level of quality than many comparable parts suppliers. When precision manufacturing becomes challenging, we outperform. All our operations are performed in a lean, clean and smart factory: from prototyping to 24-7 operations precision manufacturing.

our services

- series production of parts (24/7)

- fast track production of parts in our modelshop

- parts industrialisation studies

- manufacturing cost & risk studies

- design for manufacturing support

our expertise

We are specialised in manufacturing extreme complex parts in a reliable controlled way. Complexity in all kinds of aspects: e.g. extreme small dimensions, extreme clean, extreme accuracy, extreme shapes, extreme exotic materials etc.

We are experienced in:

- manufacturing engineering

- quality engineering

- cost engineering

- NPI program management

- SPC/QA process improvement

our competences

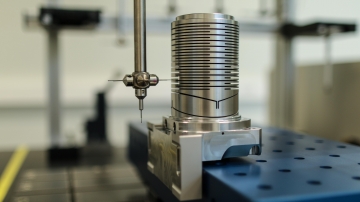

- precision milling

- precision turning

- EDM

- 40x precision finishing

- cleaning

- parts inspection and certification

- laser welding

- surface plating

- opitcal anodizing

- vacuum brazing

- passivation PVD CVD

- micro etching

- grade 2 cleaning

our handshake with clients

- We are a reliable supplier who controls quality, delivers on time and at a fair price.

- We always seek to balance product functionality, cost, risks, durability, and delivery time linked to the priorities of our clients.

- Our high level process and quality control is based on advanced spc techniques and implemented in quality dashboards accessible for our clients.

Special metals & plastics

- OFCopper

- TZM

- Molybium

- 316Ti

- Inconel 6-4

- Titanium

- AlCu

- Invar

- ACP5080s

- BeCu

- PEEK

- PPSU

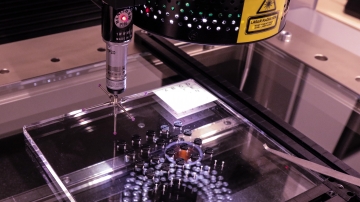

optical inspection

- In-house state of the art optical inspection tools/CMM’s.

- Fast contactless part inspection with Zeiss optics, certified measuring within a range of microns.

- Fit for fragile and complex parts with a high accuracy spec.

integrated cad cam

- NPI programs start with part specifications, designing manufacturing instructions and CADCAM programming.

- There is a direct and online link between our CNC machines and our CADCAM office.

- Multiplatform CADCAM software fit to import all modern design solid formats

- Optimising 3 or 5 axis programs in close cooperation with our tooling centre.

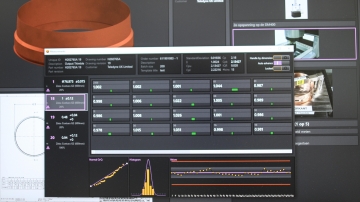

process control

- In-house developed software for inline inspection and online statistical process control.

- Critical dimensions logged and filed and Cpk values monitored to optimise quality control.

- Applicable in a.o. medical parts manufacturing.

- Furthermore we implement 100% inspections, FAI’s, production risk assessment, Gage R&R studies etc.

parts examples

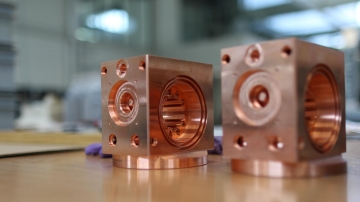

large medical part

- Certified source from oxygen free copper

- High complexity in manufacturing.

- Produced in the mid-high volume range used for assemblies.

- Machining OFCu parts requires special tooling and cutting fluid, crucial to achieve our customers' end specifications.

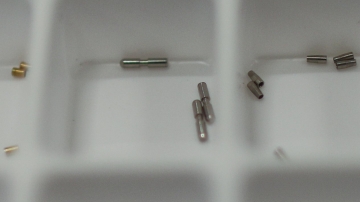

small medical parts

- Our competence in manufacturing small medical parts is comparable to parts manufacturing for Swiss watches.

- One of the machines central in manufacturing these parts is a so called swiss-type machine, “The Tornos Nano”.

- Series vary from from one-off up to high-volume.

carrier frame

- Carrier frame parts produced according to vacuum compliancy.

- Special 5000 series aluminium is being used to achieve high accuracy, cleanliness, minimal internal stress and porosity.

Dynamic Link

- Dynamic link designed and produced from monolithically 6-4 Titanium.

- Design optimised for functionality and manufacturability.

- Heat treatment and tempering are applied to achieve stability and accuracy.

- Machined by EDM with tungsten or Cu wire according to cleanliness standards.