markets and applications for which we supply parts, modules and systems

semicon

- lithography equiment

- research tools

- production tooling

- positioning equipment

- linear motors

Medical

- equipment for medical treatment

- x-ray tubes

- brachytherapy

- respiration equipment

- rf high power microwaves for MRI

display

- research tools

- manufacturing equipment

- depositioning equipment

- display handling equipment

aerospace

- cryogenic equipment

- mass spectrometers

- sensors & detectors

Analytical

- high-end analytical instruments

- cryogenic equipment

- analytical chambers and handlers

- Mass spectrometers

Modules example

- For a Dutch OEM, in a year we implemented an NPI program for 6 different devices.

- Building a new supply chain, implementing and improving cleanroom assembly and qualification.

- In the years to come we are focussing on redesigning various devices, making devices more robust, standardising assembly, reducing total cost and creating flexibility in the supply chain.

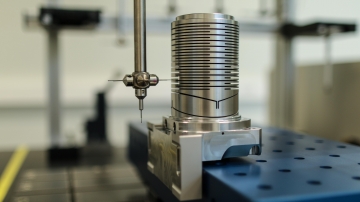

Parts example

- Dynamic link designed and produced from monolithically 6-4 Titanium.

- Design is optimized for functionality and manufacturability.

- Heat treatment and tempering are applied to achieve stability and accuracy.

- Machined by EDM with tungsten or Cu wire according to cleanliness standards

our customer base

OEMs with a need to outsource (part of) the development of machines – systems – modules. Scale-up deep tech companies who want to go to market fast. Research departments and institutes with a need for the development of new systems or tools. OEMs and first tier suppliers who need a partner in the manufacturing, assembly and test of modules, systems, critical components in low to medium series numbers.

Collaboration MEKOPP

The MEKOPP project aims to work towards efficient and sustainable production of photonic integrated circuits (PICs). This is a technology for chips that work with light (photons) instead of, or in addition to, electrical currents (electrons). PICs have the potential to be more efficient, more compact, more energy efficient and more affordable than their electronic counterparts.

In the project, two machines are being developed: a Photonics Test Prober (PTP) and Photonics Visual Inspection Tool (PVIT). These high-tech machines will aid in photonics production in a sustainable way (50% reduction in materials, energy and water use).

In this collaboration, Settels is responsible for development of the optics for alignment and inspection in the PVIT.